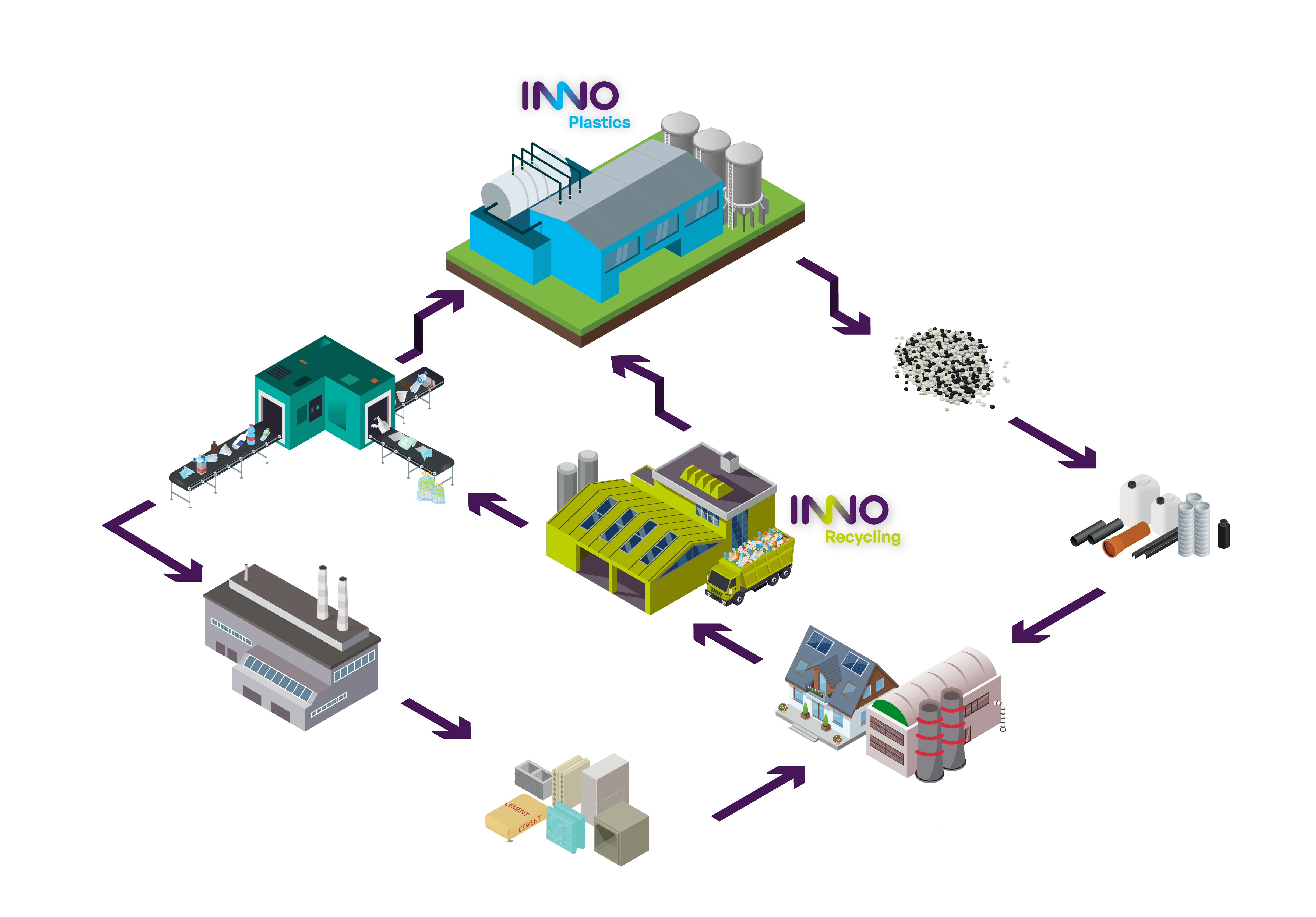

Material Cycle

Recycling Plastic Instead of Destroying It

Plastics are precious raw materials that are too valuable for single use. Plastic products should be kept in circulation for as long as possible in order to save and replace resources.

Recycling plastic makes optimum use of energy, as the gray energy is completely retained and the production of recycled plastic requires half as much energy as the production of new plastic.

Plastics Processor

High-Quality, Unmixed Regranulation

The unmixed plastics are sent to specialized plastics processors such as InnoPlastics AG in Eschlikon for processing.

There, the plastics are shredded, washed, separated and dried. The clean flakes are melted down, extruded and processed into pellets.

Cement Industry

Mixed Plastics as a Substitute for Coal

Mixed plastics that cannot be recycled are fed into the cement industry as a substitute fuel for coal. Each tonne of substitute fuel replaces 1.2 to 1.5 tons of hard coal or lignite.

Cement Products

The products made from the cement are used in Swiss house and road construction.

Households, commerce and industry

Collecting recyclable materials: in commerce, industry and at home

Household plastics should not be thrown away after use, as many of the materials are recyclable. This is where the collection bag comes in: it can be purchased at numerous retail outlets and later filled and returned to collection points. Many different recyclable materials accumulate at home, but also in industry and commerce. These include plastics, which should not be thrown away after use, as many of the materials are recyclable.

Recycling Company

Quality Control and Compacted Transportation

The collected collection bags are checked by our collection partners, such as InnoRecycling AG, for incorrect waste before the bales are compressed and transported for sorting.

Products Made from Recycled Material

From Old to New

The products made from the recycled pellets can be recycled again if they are produced in the same type. Cable conduits, canisters, films, etc. are made from the regranulate. Applications such as bottles, buckets and other products are also possible.

Regranulate

New Plastic from Old Plastic

The high-quality regranulate is used in the production of bottles, pipes or films, for example.

Sorting Plant

High-Quality Sorting with Near-Infrared

In the sorting plant, the bales are unloaded, torn open and loosened up. The plastics are transported via a complex system of fully automatic conveyor belts. Near-infrared scanners identify the different materials. Compressed air valves then separate them precisely. Despite this modern technology, a manual check is still carried out to ensure the best possible result. The sorting system thus achieves a purity value of 95 to 98%.